Koster Superpackers

For Use With Injections Resins & Gels

£277.52 – £327.39 (inc. VAT and standard delivery)

Koster Superpackers For Use With Injections Resins & Gels

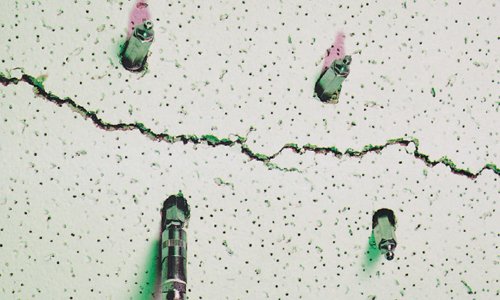

Koster Superpackers have a cone shaped flange (or Pan Head) in the gasket section that ensures that the pressure is exerted deep in the drill hole, providing an excellent seal and ensuring a permanent fixation in the drill hole. Four fins and two ridges on the rubber gasket prevent rotation of the packer during tightening and thereby facilitate optimal fixation of the packer in the drill hole. Koster Superpackers do not have a predetermined breaking point. The spanners are to be screwed off after use.

Koster Superpackers are suitable for crack injection and for area injections using pressurized injection equipment.

Holes are generally drilled with 10 – 15 cm spacing, depending on the substrate thickness and crack geometry. After drilling a hole with the proper diameter, the Koster Superpacker is installed at least 5 cm deep into the drill hole. The gasket of the packer is tightened by turning the hexagonal part of the packer clockwise first by hand and then using a wrench until the packer is fixed firmly in the hole. By turning the hexagonal spanner, the rubber gasket is pushed onto the cone shaped flange in the gasket section and pressed onto the walls of the drill hole so that a tight seal is achieved. Injection is then carried out. After the material has cured the spanner can be removed and the drill hole sealed with Koster KB-Fix 5.

13mm x 85mm Panhead – KÖSTER Superpacker 13 mm x 85 mm PH

13mm x 115mm Conhead – KÖSTER Superpacker 13 mm x 115 mm CH

13mm x 85 Conhead – KÖSTER Superpacker 13 mm x 85 mm CH

Be the first to review “Koster Superpackers

For Use With Injections Resins & Gels” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.