DryFix Epoxy Safety Coating

£41.99 – £139.20 (inc. VAT and standard delivery)

DryFix Epoxy Safety Coating

DryFix Epoxy Safety Coating is a two-part epoxy coating designed to provide a tough, durable, traction enhanced flooring for concrete and timber surfaces. Having excellent chemical and abrasion resistant properties make it ideally suitable for food production areas, workshops and all floors that demand a safe, slip resistant and hygienic surface.

Ideally suitable for production areas, warehouses, workshops, plant rooms, goods in/out areas, in fact any floor that is heavily trafficked by fork lift trucks, pallet trucks, cars and pedestrians.

Fill all holes and face up all cracks etc with Epoxy Filler or Patching Mortar.

COVERAGE: 4.5 Litres will cover approximately 25m² depending upon the site conditions.

POT LIFE: When fully mixed approximately 30 minutes. Extended pot life at lower temperatures, reduced at high temperatures.

CURING /HARDENING TIME: Tack free in 12 hours @ 20 C. Re-coatable in 12 hours @ 20 C. Do not use at temperatures below 4C. Full cure in 7 days.

SLIP RESISTANCE: The fully cured product offers excellent slip resistance. Certified when tested to BS 7976-2. Mean PTV (Dry) 70 (Low Risk of Slip) Mean PTV (Wet) 60 (Low Risk of Slip)

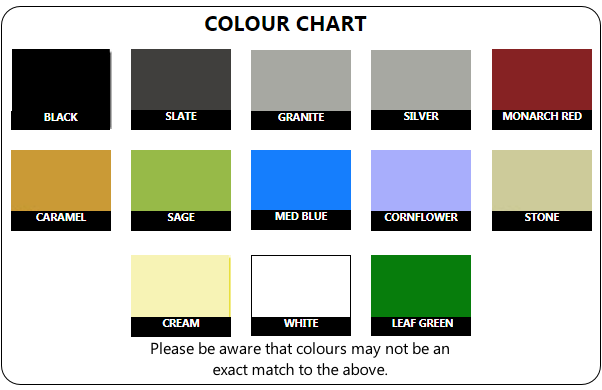

COLOURS: Available in a range colours—see colour chart.

APPLICATION: Apply the coating immediately after mixing by roller. One or two coats can be applied. For best results apply two coats. Do not apply too generously otherwise the slip resistance will be compromised. Apply at a coverage rate of approximately 25 square metres per 4.5 litre pack. The second coat must be applied within 7 days. If this period is exceeded then lightly abrade the surface with carborundum papers to form a key for the second coat.

Data Sheet – Dryfix Epoxy Safety Coating

Delivery

The carriage charge for your order is shown at the checkout stage. At this stage you have the option to upgrade for a next day delivery. The vast majority of Next Working Day Deliveries will arrive the following day. Please note that this is not a ‘guaranteed’ service and Alliance Remedial cannot accept any liability for deliveries which arrive beyond this period. Where instruction for items to be ‘left safe’ or in a ‘specified location’, have been given, Alliance Remedial or its courier cannot accept any responsibility for loss or damage.

Please note Alliance Remedial cannot accept any liability if you are inconvenienced financially or otherwise if an order is delivered late by a 3rd party courier service, is not fulfilled by a 3rd party courier service, or arrives broken or incorrectly.

* Surcharges may be applied for deliveries to certain Post Codes. These include, but not limited to, the following Post Codes –

Aberdeen – AB31, AB33-38, AB45, AB53-56

Falkirk – FK17-21

Outer Hebrides – HS1-9

Inverness – IV1-3, IV10-28, IV30-32, IV36, IV40-49, IV51-56 & IV99

Kilmarnock – KA27-28

Kirkwall – KW1-3, KW5-17

Paisley – PA20-38, PA41-49, PA60-78 & PA80

Perth – PH17-26, PH30-44, PH49-50

Lerwick – ZE1-3

Belfast – BT1-49, BT51-58, BT60-71, BT74-82, BT92-94

Isle of Man – IM1-9 & IM99

Isle of Wight – PO30-41

Truro (Scilly Isles) – TR21-25

Returns & exchanges

In accordance with the Consumer Contracts Regulations, (Distance Selling Regulations) you have the right to cancel the contract within 30 days from the date of delivery. Please note that you will be responsible for the method and costs of returning the goods to us. Goods should be returned in a merchantable ready for re-sale condition to receive a full refund.

Goods being returned by the Purchaser because they are no longer required can be returned 30 days after the date of delivery. The Purchaser is responsible for arranging and paying for return shipment costs which should be insured. If goods arrive back to us in damaged condition which was not declared as the reason for the return a refund will not be provided. Special offers and “kits” are only returnable in full and not in part.

Goods of a bespoke or specialist nature; Paints, Epoxy products, Tanking renders, Renovating plaster and remedial chemicals cannot be returned for refund. This is due to their perishable nature, storage and transportation restrictions. Please satisfy yourself that you are ordering correctly or if you are ordering for contracted works the works will not be cancelled.

At our discretion, we may entertain a return of goods beyond 30 days.

For goods of a specialist nature, we reserve the right to apply a return to stock admin fee of up to 35% the value of the goods plus shipping cost.

Our returns policy is in accordance with the Consumer Contracts Regulations and do not extend to B-2-B purchases or for resale purposes.

You are required to email us of your request to return goods through our website: Product Returns

Goods should be returned to our head office address.

Damages

In the unlikely event you receive goods that are damaged, the courier note must be signed DAMAGED for Alliance Remedial to be able to issue any refund or credit. Should goods be missing from an order, Alliance Remedial should be notified within 48 hours of delivery. Any notification after this period will not be accepted.

Be the first to review “DryFix Epoxy Safety Coating” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.