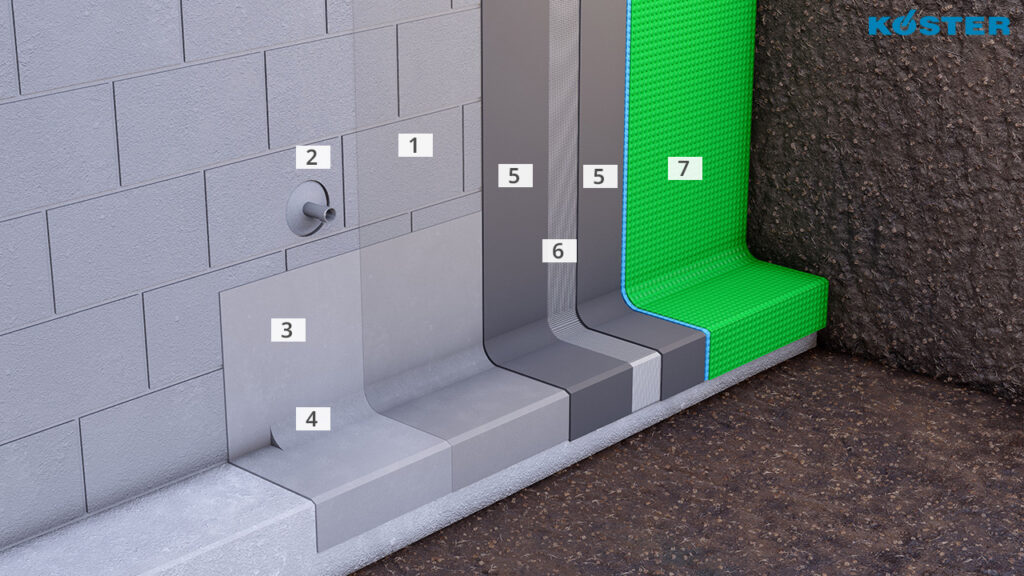

Waterproofing Systems

External Basement Waterproofing with Mineral Based Waterproofing Systems

Mineral sealing slurries are especially robust waterproofing systems with extremely good adhesion to mineral surfaces. They are not affected by moist surfaces and become an integral part of the building structure on which they were applied. Mineral sealing slurries are paste-like and are applied seamlessly to the building element being waterproofed. They are easy and safe to apply and can be installed as rigid or crack bridging systems.

On clean, solid, stable, gypsum free mineral substrates Koster Polysil TG500 is applied as a primer. This immobilizes salts present in the substrate and the substrate is solidified.

Pipe penetrations are waterproofed using Koster KB-Flex 200 and sealed with Koster KB-Fix 5. Alternatively these areas are to be attached to the waterproofing using proper sleeves or flanges.

The actual area waterproofing is achieved using Koster NB 4000 in two layers. The installation of Koster Glass Fibre Mesh is recommended between the Koster NB 4000 layers to achieve an especially visco-plastic waterproofing layer. In areas especially in danger of water creeping behind the waterproofing such as wall-floor junctions, a substrate preparation with Koster NB 1 Grey mixed with Koster NB 1 Flex is applied. To avoid stresses in the elastic waterproofing, rounded fillets made of Koster Repair Mortar are installed in interior corners.

Before backfilling the waterproofing is protected from mechanical damages and settling with Koster SD Protection and Drainage Sheet.

Always adhere to the specifications in the respective Technical Guidelines.

1 Primer

KÖSTER Polysil TG 500

2 Waterproofing pipe penetrations

KÖSTER KB-Flex 200

3 Preparing wall/floor junctions

KÖSTER NB 1 Grey

4 Installing fillets

KÖSTER Repair Mortar Plus

5 Waterproofing layer

KÖSTER NB 4000

6 Reinforcement

KÖSTER Glass Fibre Mesh

7 Protection of the waterproofing layer

KÖSTER SD Protection and Drainage Sheet 3-400